That’s our main activity : planning and supply of dies for every kind of pellet mill, for any kind of trade mark and machine model, independently by its size. After the whole definition of all technical details with the Customer, we build our die using Italian forjed steel rings of top quality only. Once completed the turning and boring works, we carry out the perforation process by automatic gun-drilling machines of last generation. And then heat treatment, side grinding, countersinking of every single hole, dimensional check, quality control, packing and shipping.

All made upon our usual standard.

|

|

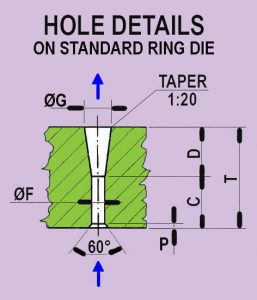

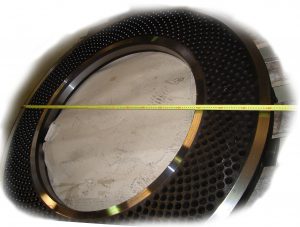

RING DIES OF ANY KIND, SIZE, TRADE MARK, SHAPE AND DIMENSIONS,

up to Ø1000 mm. inside

|

|

|

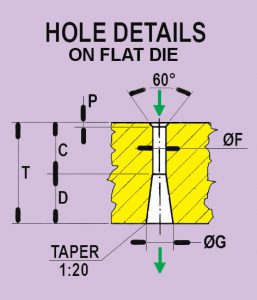

For main technical terminology and for whole details about |

|

||

FLAT |

RING |

|||

FLAT DIES OF ANY KIND, SIZE, |

TRADE MARK, SHAPE, MODEL |

up to Ø1850 mm.

|

|

COMPLETE ROLLERS AND ROLL SHELLS FOR ANY KIND OF PELLET MILL

|

|

HAMMERS, PINS AND PERFORATED GRIDS FOR HAMMER MILLS

|

|

Ask for the Certificate of Origin and

of Quality of all your spare parts.

To get them it is not your right only: it’s your convenience!